Responsible Recycling: The Power of Documentation

Proper documentation and certifications are integral to RIMECO’s operations, ensuring that every aspect of handling waste and scrap metal is conducted with the highest standards of safety, quality, and environmental responsibility.

Our facility is accredited with ISO 14001 for environmental management and ISO 9001 for quality management, guaranteeing the purity and sustainability of our processes. By maintaining meticulous records and certifications, we uphold transparency and accountability, ensuring that every transaction and process meets regulatory and industry standards.

This commitment to documentation not only enhances trust with our partners but also reinforces our dedication to promoting a sustainable future through responsible recycling practices.

Finding potential where others see waste

Scrap metal, often overlooked, holds hidden value that we specialise in uncovering. We deal in a wide range of ferrous and non-ferrous metals, from steel products and reusable materials to foundry scrap and even granulated cable plastics.

Whether you’re looking to offload excess materials or source high-quality metals for your next project, RIMECO is your one-stop shop.

Our advanced processing facilities ensure the highest quality materials, making us your trusted partner for reliable and efficient metal trading. Join us in promoting sustainability and maximizing the value of your metal resources.

From Trader to Trailblazer:

RIMECO Reimagines Metal Recycling

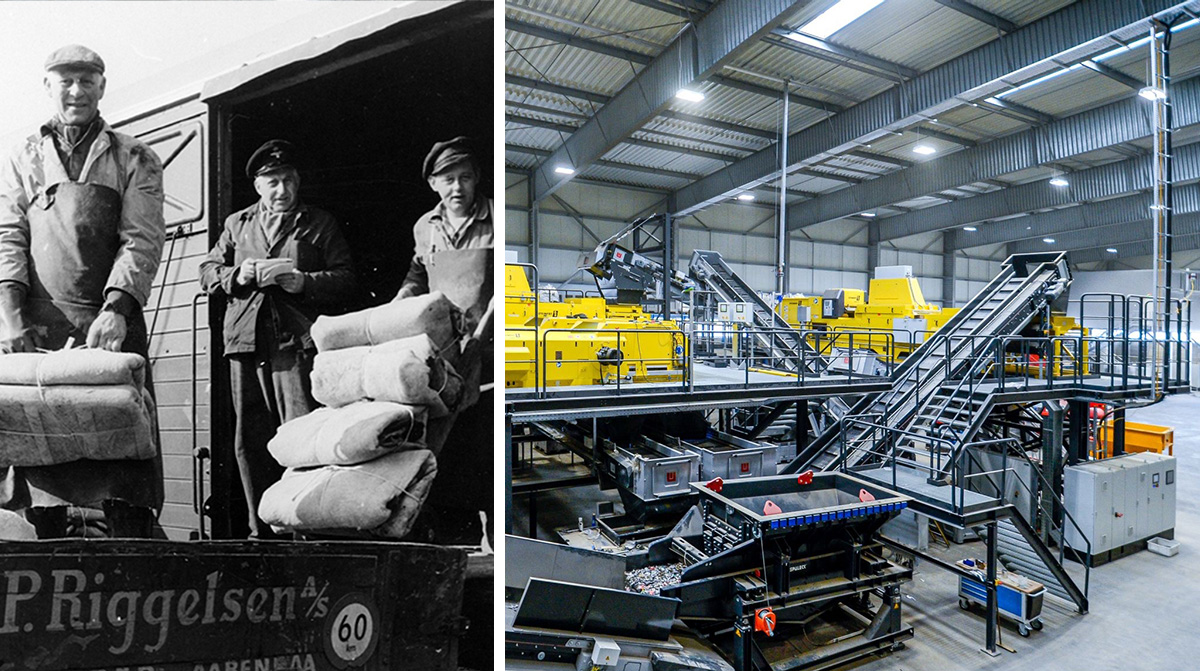

RIMECO’s legacy in scrap iron and metal trading stretches back to 1888. While our expertise in market dynamics secured our place as an industry leader, we recognized a higher calling in today’s world: sustainability.

That’s why RIMECO has undergone a bold transformation – from a trading company to a cutting-edge processing powerhouse. We’ve invested heavily in state-of-the-art recycling facilities, tackling complex and “low-value” scrap that others turn away. We extract and refine valuable resources, minimizing waste and driving environmental progress.

This isn’t just about our business; it’s about pioneering a circular economy where resources get a second life.

Our evolution from trade to process-driven powerhouse signifies our unwavering commitment to innovation, sustainability, and creating value from what was once deemed waste.

Join RIMECO on the path to a greener future.